The power of the Scanning Electron Microscope (SEM) as an imaging tool is well known. Exceptional resolution, incredible depth of field and high magnifications allow an SEM equipped with a secondary electron detector to produce images detailing surface topography with a wide depth of focus. In addition, the use of a backscatter electron detector and an energy-dispersive x-ray spectroscope (EDS) permits the collection of elemental information from the sample, allowing you to literally look beneath the surface and see the elemental composition. There are, however, some limitations on the sample itself to be imaged with an SEM.

The power of the Scanning Electron Microscope (SEM) as an imaging tool is well known. Exceptional resolution, incredible depth of field and high magnifications allow an SEM equipped with a secondary electron detector to produce images detailing surface topography with a wide depth of focus. In addition, the use of a backscatter electron detector and an energy-dispersive x-ray spectroscope (EDS) permits the collection of elemental information from the sample, allowing you to literally look beneath the surface and see the elemental composition. There are, however, some limitations on the sample itself to be imaged with an SEM.

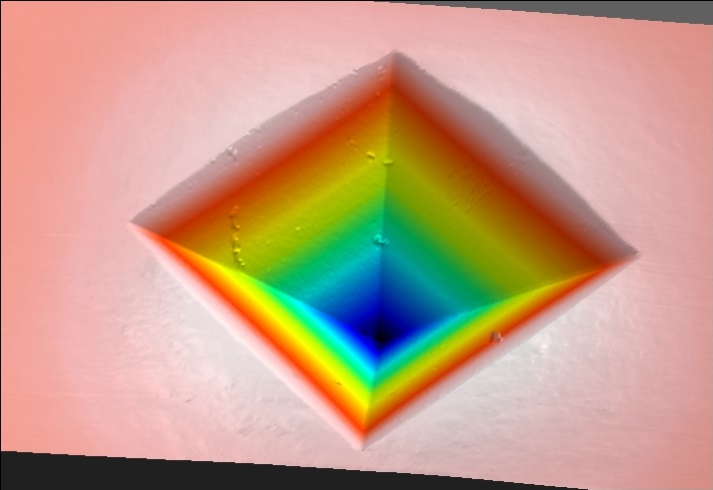

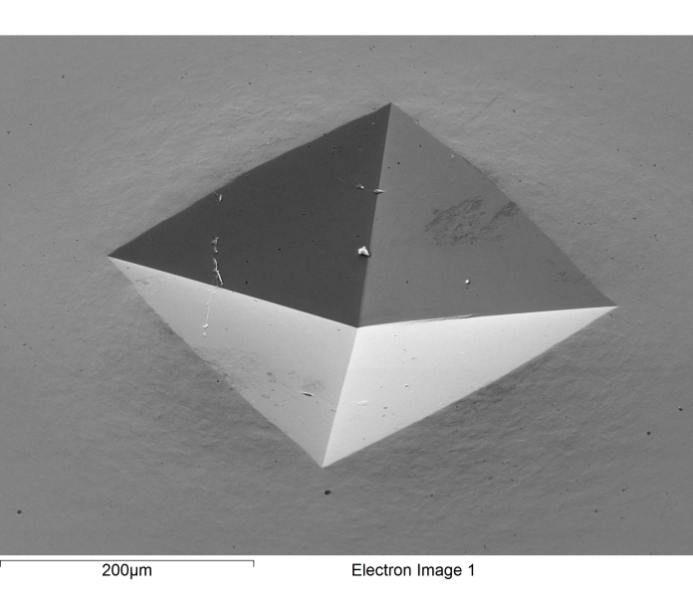

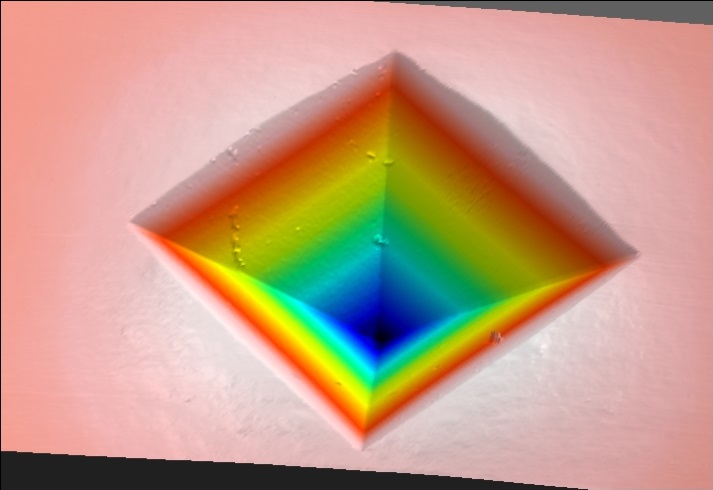

In order to image with an SEM, the sample must be conductive to allow the electrons that bombard the sample to dissipate to ground and not be repelled by a charging sample. If the sample is electrically insulating, the surface of the sample retains the electrons, gaining an overall negative charge that then deflects away subsequent electrons which in turn prevents imaging. For samples that are not naturally conductive, a conductive layer (carbon or metal) is applied to prevent this charging effect, thus modifying the sample. A second limitation is that the sample must be small – small enough to fit into the SEM. This, of course, is not an issue for some samples, but for others it can mean breaking, cutting or scraping the sample to create a suitable sub-sample. Lastly, in order to clear a path for the electron beam used for imaging, the sample chamber is evacuated to achieve a high vacuum and eliminate the interference caused by molecules in the air. Therefore samples that are sensitive to vacuums or that may emit gases or vapours under vacuum may require lengthy preparations before imaging by SEM. Laser interferometry (LI) offers an alternative imaging tool that is comparable to SEM imaging with a much shorter list of sample limitations. LI does not require a conductive sample as the imaging beam is a low-power laser rather than an electron beam. The sample size can be much larger – up to 10cm by 10cm by 5cm – and the sample can weigh as much as 12kg and still be analysed. Lastly, the scans occur in the open air ensuring that there is no issue with scanning samples that may emit gas or vapour products under vacuum. Of course, LI is by no means the equal of SEM when it comes to very high magnification work but Figures 1 and 2 below show that it is possible to consider the two as comparable for lower magnifications (each edge of the pit is 14.2µm in length). In fact, when a study is made of the imperfections on the back-left plane and the surface ‘rippling’ on the four edges of the pit, the comparison becomes more obvious. In addition to imaging, LI can be used to make a wide range of measurements ranging from simple pit depths to waviness/roughness profiling and direct surface comparison. All this gives LI a unique skill set ensuring its usefulness as an imaging and measurement instrument for a wide range of samples.

Laser interferometry (LI) offers an alternative imaging tool that is comparable to SEM imaging with a much shorter list of sample limitations. LI does not require a conductive sample as the imaging beam is a low-power laser rather than an electron beam. The sample size can be much larger – up to 10cm by 10cm by 5cm – and the sample can weigh as much as 12kg and still be analysed. Lastly, the scans occur in the open air ensuring that there is no issue with scanning samples that may emit gas or vapour products under vacuum. Of course, LI is by no means the equal of SEM when it comes to very high magnification work but Figures 1 and 2 below show that it is possible to consider the two as comparable for lower magnifications (each edge of the pit is 14.2µm in length). In fact, when a study is made of the imperfections on the back-left plane and the surface ‘rippling’ on the four edges of the pit, the comparison becomes more obvious. In addition to imaging, LI can be used to make a wide range of measurements ranging from simple pit depths to waviness/roughness profiling and direct surface comparison. All this gives LI a unique skill set ensuring its usefulness as an imaging and measurement instrument for a wide range of samples.