DIN’t you hear? Corrosivity testing for bulk shipping is having an overhaul.

As many of you are aware, shipping requirements regulations are constantly being updated to ensure maritime and dockside safety. One of the recent focal points has been the determination of Class 8 and MHB corrosivity in bulk cargoes.

Late last year AMSA released Exemption 5450 which allows certain cargoes to be tested using an alternate test method for corrosivity determination. These cargoes have been shown to be consistently problematic when it comes to the determination of the likelihood of localised corrosion.

This exemption only applies to Coal, Bauxite, Iron Ore and Iron Ore Fines. For concentrates, you’ll be looking at Exemption 5451 for now.

So what is this alternate test?

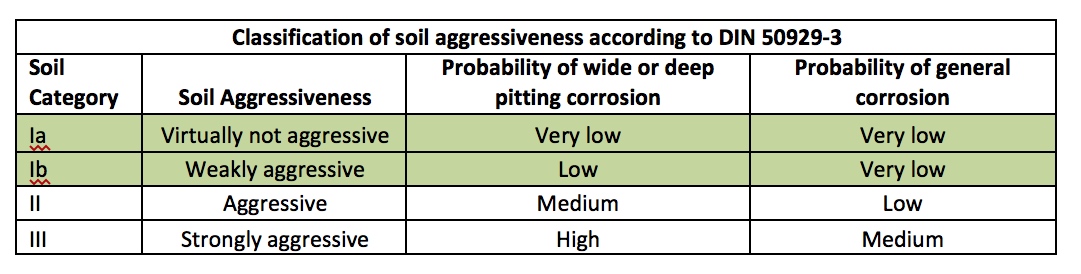

Instead of trying to experimentally simulate the environment in a ship’s hull and measuring the corrosion rate, DIN 50292-3 allows a series of chemical and physical tests of the product to be used to predict the likelihood of the product causing serious localised corrosion.

The result of this change is that producers can obtain a more consistent result with a suite of standard laboratory tests, and be confident that their product is as safe as they think!

A significant amount of research and parallel testing has been performed by Microanalysis Australia and Curtin University on behalf of a number of industry bodies to verify the efficacy and practicality of the new test.

Please note that this exemption supersedes EX5389.

Ask us about MHB and IMDG classification for your cargo!