On Wednesday 1st November, Microanalysis held a special information evening for the Australasian Corrosion Association (ACA) and Surface Coating Association Australia (SCAA) professional associations.

Pulling everyone away from the tasty nibbles and drinks, the 12 members had a guided tour of the Laboratory to learn a little of what Microanalysis Australia is up to in the corrosion field as well as in a diverse range of other industry sectors.

Exploring the lab, the delegates learned about spatial elemental analysis in the two Zeiss SEM/EDS systems, identifying corrosion products versus naturally occuring ferrous phases in the two Philips/PANAlytical XRDs, sizing microbes in the Malvern Mastersizer, understanding settling rates using a Sedigraph, Hiac Royco Particle Counters for contaminat concentration determination in liquids – particularly important for corrosion inhibitor cleanliness and surface corrosion and pitting analysis on the Solarius Laser Profilometer.

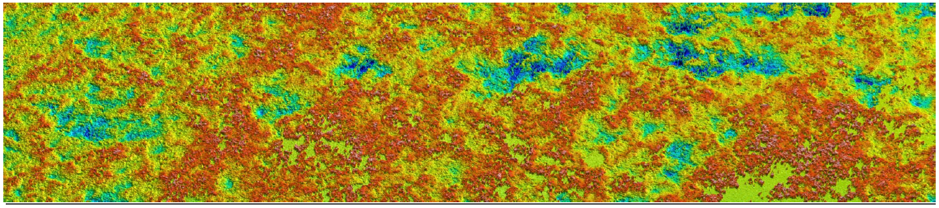

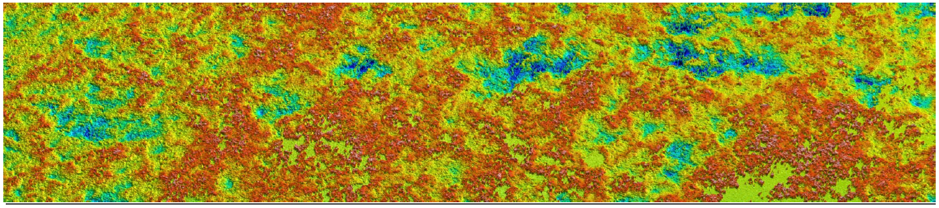

The group learned about the UNDG testing that Curtin University and Microanalysis have been involved in with regards the C1 ‘Localised Corrosion – Intrusion depth’ research. The Solarius Profilometer has been an invaluable tool in terms of scanning large corroded areas to obtain pit depth and profiles.

After the tour, the group returned to the drinks and food where Nimue Pendragon and Owen Carpenter presented some information about failure analysis using SEM EDS, bulk goods testing by ADG and IMDG, and UNDG C1 corrosion analysis by laser profilometer. Download a copy of the presentation below.

We hope an informative evening was had by all.

Energy Dispersive X-ray Spectrometry for Determining Chloride Concentration Profiles in Concrete

Liam Holloway1 and Nimue Pendragon2

1Principal Engineer, MEnD Consulting

2Lead Consulting Scientist, Microanalysis Australia

Abstract: Assessing the condition or durability performance of existing reinforced concrete infrastructure can involve a broad range of investigation techniques. Investigations during the life of the structure can be used to inform the asset management process. A typical test reg ime will involve visual inspection, cover meter surveys, electrochemical testing, strength assessments, and the collection of core samples for a range of analytical chemical testing. In cases where there is a perceived risk of Alkali ‐ Silica Reaction occurr ing, the testing regime may also include uranyl acetate fluorescence screening, or petrography. Petrography can be done using optical microscopy or Scanning Electron Microscopy (SEM). While petrography can be used to determine the likelihood of ASR, it is also able to give an indication of other concrete properties including, porosity, cement content, and strength. SEM petrography with the combination of Energy Dispersive X – Ray Spectroscopy (EDS) can also provide semi quantitative assessment of other proper ties including but not limited to; aggregate cement ratio, and chloride content. In this paper, we propose that the use of SEM petrography and EDS can provide a more efficient and cost effective way to gather most of the information required to perform dur ability assessments of existing structures. While the use of SEM petrography is not a new concept , using EDS to determine chloride concentration profiles is a novel approach. In this paper, we compare chloride profiles from SEM – EDS against those gained fr om conventional wet chemistry. The results from both assessment techniques were fit to estimate the apparent chloride diffusion coefficients .

For a full copy of the paper please use the following link:

From lithium to heavy metals, Microanalysis offers customisable mineral liberation and association analysis for ores and concentrates of all kinds. Complementary to our petrographic capabilities, Microanalysis can analyse a range of particulate sizes up to 3 mm and provide additional manual analysis for particles >3 mm.

INCA Mineral by Oxford Instruments (product information available here) is a software package allowing for automated mineralogical analysis including mineral liberation, association data, size, morphology, deportment and more. INCA Mineral can emulate QEMScan data outputs, and be customised so you get only the information you need.

Usually QEMScan is recommended for particles up to to 500 µm – using a custom setup of INCA Mineral, our technique can analyse particles up to 3 mm. Still too small? Microanalysis has developed an equivalent, manual, technique for particles >3 mm using a combination of correlated optical and electron imaging, EDS and X-ray mapping.

Speaking of small – light elements (H, He, Li, Be) are always problematic from an analytical point of view. Too small for XRF and even EDS, indirect detection methods are required to ‘see’ lithium in mineral samples. Using image contrast and Si:Al ratio we differentiate spodumene and petalite from non-lithium aluminosilicate minerals, allowing us to determine the liberation and association of lithium bearing minerals. Lithium-bearing micas are even trickier, with a wide range of elemental compositions, so we combine our geological and petrographical expertise to characterise the lithium bearing micas and create a ‘fingerprint’ for the lithium bearing species, using the trace substitutions and specific elemental ratios to classify these minerals. We cross check our data with XRD results to give a comprehensive mineralogical assessment.

Whether it’s characterisation of light element minerals, characterising impurities in high purity sands, or simply gaining an idea of what your sample is, Microanalysis can help you get the most from your samples using our technology and expertise.