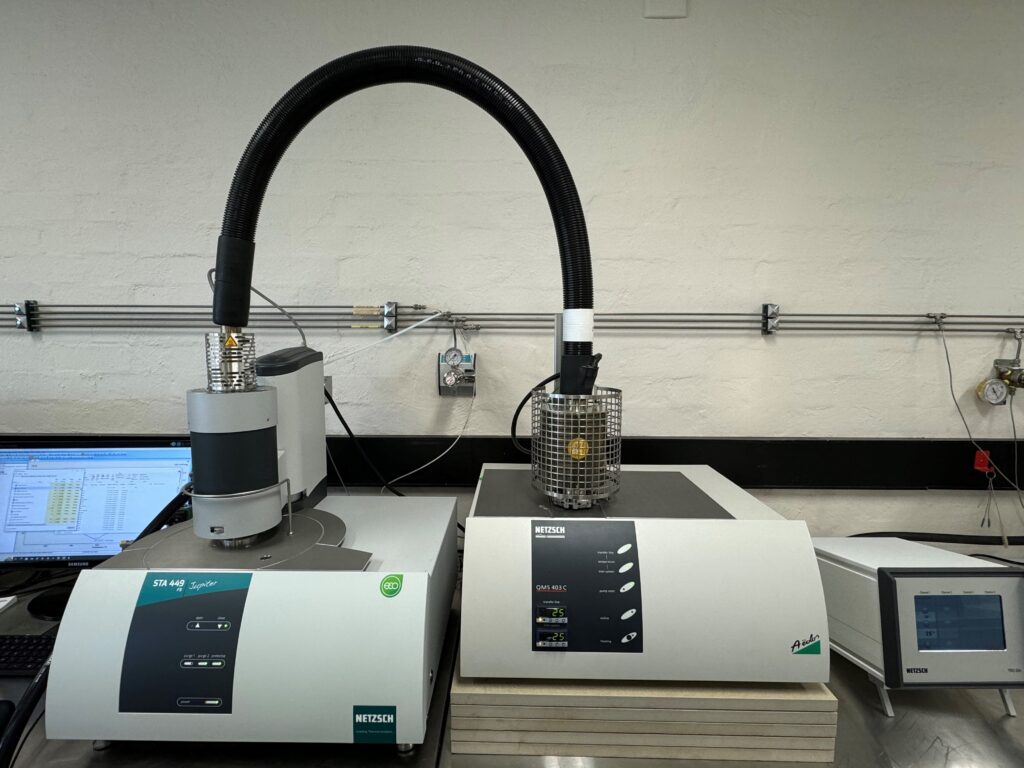

Microanalysis Australia is equipped with the NETZSCH STA 449 F5 Jupiter, a high-performance DSC/TGA instrument capable of simultaneous thermal analysis from room temperature up to approximately 1550 °C. For evolved gas analysis, the system is externally coupled with the MS 403 Aëolos II mass spectrometer, which operates over a mass range of 0–300 amu, enabling real-time identification of gases released during thermal events.

Our default testing conditions use alumina crucibles, a nitrogen atmosphere, and a heating rate of 10 K/min. For specific heat capacity (Cp) measurements, we utilize the sapphire method with Pt/Rh crucibles and alumina liners to ensure high accuracy.

We offer flexibility in experimental setup—crucible materials, gas atmospheres, and heating rates can be customized to meet the specific requirements of our clients.

Our methods are compliant with industry standards including ASTM E794 (enthalpy of transition, melting and crystallisation) and ASTM E1269 (specific heat capacity by DSC), among others.

Discovering the intricacies of materials is made possible using Thermal Analysis with the revolutionary DSC/TGA MS machine. This cutting-edge instrument integrates Differential Scanning Calorimetry (DSC), Thermogravimetric Analysis (TGA), and Mass Spectrometry (MS) to unveil a comprehensive analysis of substances. By precisely measuring thermal properties, weight changes with temperature, and molecular composition simultaneously, researchers gain unprecedented insights into chemical reactions, decomposition processes, and material stability. Whether probing pharmaceuticals, polymers, or environmental samples, the DSC/TGA MS machine empowers scientists with unmatched accuracy and depth, driving innovation across scientific disciplines.

The DSC/TGA MS machine finds applications across a wide range of industries and scientific disciplines:

- Polymer Research: It enables detailed analysis of polymer degradation, stability, and thermal transitions, crucial for optimizing material properties in industries from plastics to biomedical materials.

- Pharmaceutical Development: Researchers use it to study drug stability, compatibility, and formulation behaviours under varying conditions, ensuring the safety and efficacy of pharmaceutical products.

- Environmental Science: It aids in environmental monitoring by analysing organic pollutants, identifying volatile compounds in soil and water samples, and studying the decomposition of biomaterials.

- Materials Science: In fields like metallurgy and ceramics, it provides insights into phase transitions, oxidation processes, and thermal stability of materials, guiding the development of new alloys and composites.

- Food Science: It helps in evaluating food quality and safety by monitoring changes in food components during processing and storage, detecting contaminants, and assessing shelf-life.

- Fuel and Energy: Researchers utilize it to analyse the thermal behaviour and combustion characteristics of fuels, contributing to the optimization of combustion processes and development of alternative energy sources.

- Biomedical Research: It supports the study of biomaterials, including tissue engineering scaffolds, drug delivery systems, and medical implants, ensuring their stability and biocompatibility.

Overall, thermal analysis using the DSC/TGA MS instrument serves as an indispensable tool for advancing research, development, and quality control across various scientific and industrial fields. Its ability to provide simultaneous, detailed information on thermal, weight, and molecular properties enhances understanding and innovation in material science and beyond.

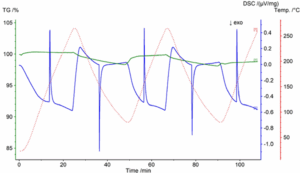

DSC heating-cooling peaks of Indium sample

Typical heating-cooling peaks of a sample

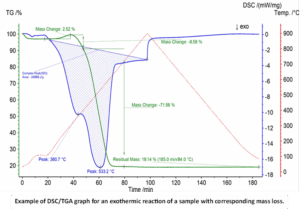

Example of DSC/TGA graph for an exothermic reaction of a sample with corresponding mass loss.